Machine & Spark Eroding

On-Time Project Delivery

We consistently deliver projects on time and within budget, ensuring your deadlines are met without compromising quality.

Customer Satisfaction

With a focus on quality and client relationships, we maintain a high customer satisfaction rate, with a significant percentage of our clients returning for repeat business.

Quality AssurED

Our products undergo rigorous quality assurance, including batch testing and life cycling, ensuring that every item we manufacture meets the highest standards of reliability and performance.

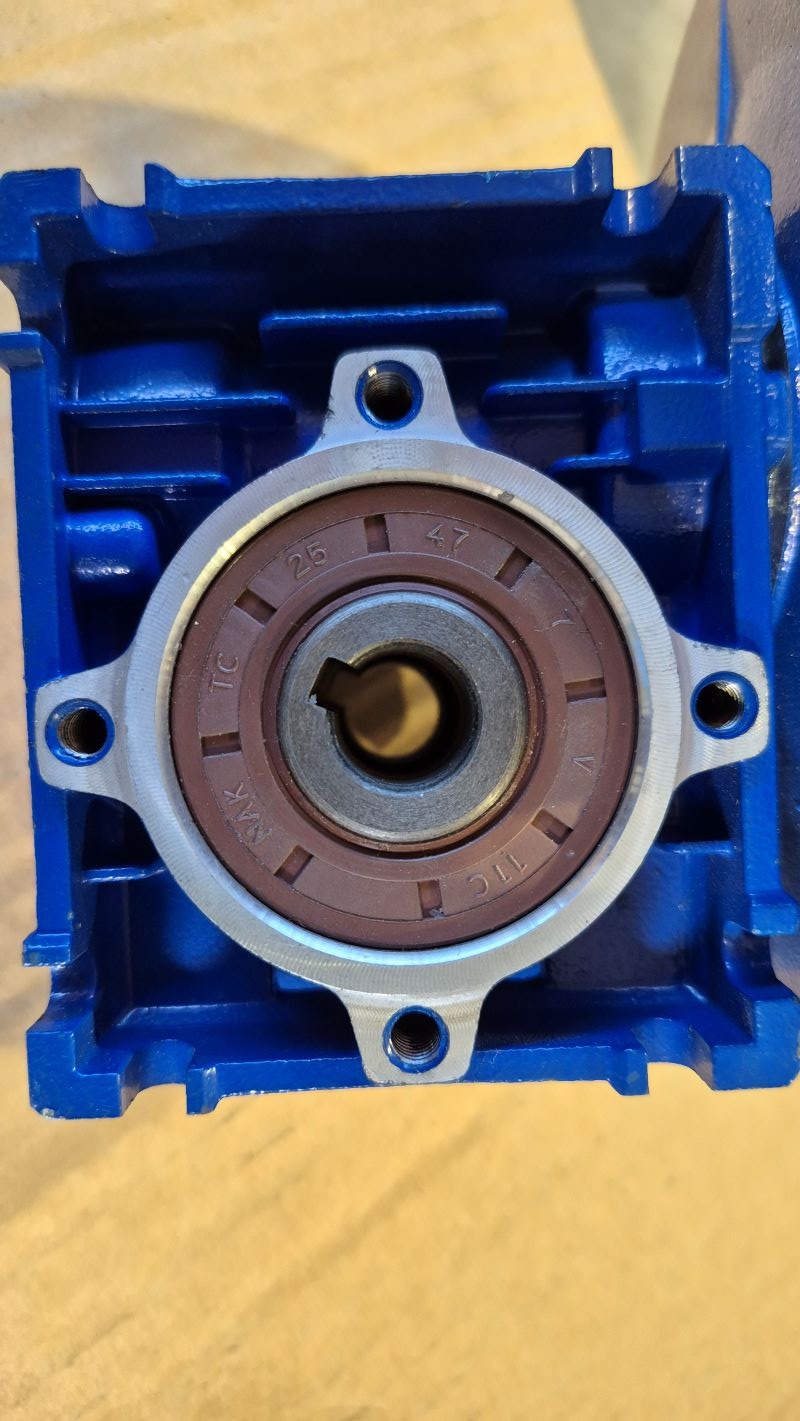

Precision Machining

Spark eroding, or EDM – electro-discharge machining, is a cost-effective way of removing material accurately, by way of a current discharge between a couple of electrodes which are separated by a dielectric liquid subject to voltage. During this spark erosion service & process, the liquid acts as both conductor and cooling agent.

Design and Planning Expertise

At Smartweld, our service goes far beyond just machining. We bring foresight and creativity to every project, offering design and planning support to optimise your outcomes. By working closely with our clients, we ensure that each project is customised to your specific requirements while keeping efficiency and cost-effectiveness at the forefront.

Our team will:

- Assess Your Needs Understand the unique challenges of your project.

- Develop Custom Solutions Use our expertise to create innovative designs.

- Ensure Seamless Execution Deliver a polished result that aligns with your goals.

Materials that can be spark eroded are

Spark erosion is suitable for a wide variety of materials, including:

- Tungsten

- Numerous stainless steels

- Carbide

- Aluminium

- Magnesium alloys

- Titanium

- Hard alloys

- High-strength metals.

Our process ensures superior results, regardless of material hardness or complexity.

Common situations that require a spark erosion service are

- Or creating a keyway into a blind hole where normal engineering practices are not practical.

- Stud removal from an engine head or automotive housing.

- Removing a broken engineer’s tap inside a blind hole.

No Mechanical Stress

Because machine spark eroding is a non-contact process, it eliminates mechanical stresses that could damage delicate components. This makes it perfect for intricate designs and precision parts.

Machine & Spark Eroding Services

Lathe & Turning Services

Lathe turning is all about shaping materials like metal or wood with precision. This service is ideal for creating symmetrical parts like shafts, cylinders, and custom components for industrial use, combining speed with accuracy to meet your unique requirements.

Spark Erosion Services

For highly detailed and complex metal components, spark erosion is the perfect solution. Using advanced electrical discharge technology, this service creates precise shapes in hard materials, making it ideal for specialized industrial applications.

What our clients say