Press Brake Folding

On-Time Project Delivery

We consistently deliver projects on time and within budget, ensuring your deadlines are met without compromising quality.

Customer Satisfaction

With a focus on quality and client relationships, we maintain a high customer satisfaction rate, with a significant percentage of our clients returning for repeat business.

Quality AssurED

Our products undergo rigorous quality assurance, including batch testing and life cycling, ensuring that every item we manufacture meets the highest standards of reliability and performance.

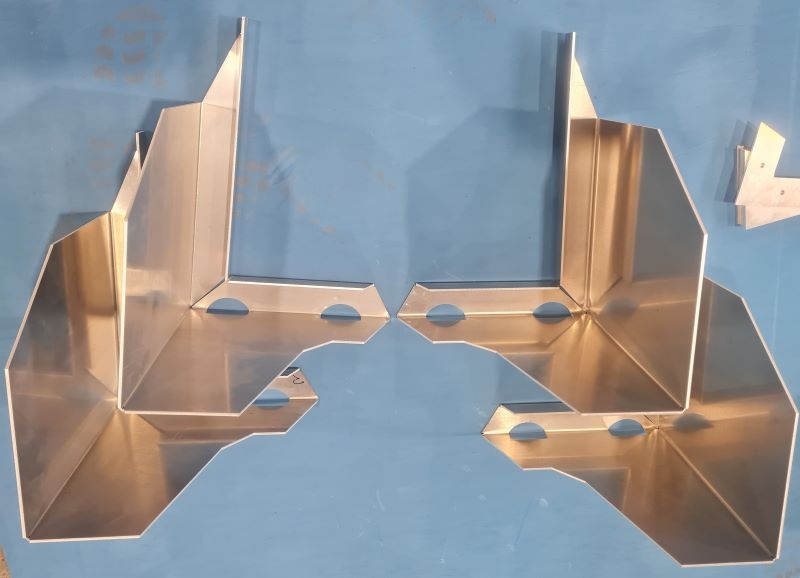

Press Brake Folding for your Project

Are you looking to take your metal fabrication to the next level? A press brake is the ultimate tool for precise and efficient metal folding, for one off and production work. Whether you’re crafting custom brackets, machinery guarding, or intricate structural components, a press brake delivers unmatched precision and versatility.

With our CNC press brake, we can create/fold quality components for engineering projects in such industries as construction, Landscape, manufacturing, just to name a few. Outsourcing this process is far more cost effective than investing in expensive equipment and having to train staff. Let’s build something great!

Why Press Brake Folding?

- Cost-Effective: Reduce waste and labour costs by automating complex bending tasks.

- Exceptional Accuracy: Achieve perfect angles and folds every time.

- Time-Saving Efficiency: Streamline production with repeatable results, reducing manual adjustments and rework.

- Versatility: Handle a wide range of materials and thicknesses, from thin sheets to heavy plate.

What is Press Brake Folding?

Smartweld’s sheet metal folding services involve a metalworking process used to bend or shape sheet metal into specific angles or forms using a press brake machine. It involves placing the sheet metal or plate between a moving top blade and stationary die to form the shape required. The top blade is normally hydraulically driven and applies pressure, forcing the metal into the die to achieve the desired bend or fold.

Advantages of Press Brake Folding

- Customizable top blades and dies for diverse applications.

- High precision and repeatability.

- Can handle various materials and thicknesses.

Applications of Press Brake Folding

- Creating formed parts for structures, and enclosures.

- Manufacturing brackets and metal supports.

- Shaping components for mass production where repeatability in key.

This process is crucial for producing durable and accurately shaped metal components.

Our Press Brake Folding Process

Final Inspection: Ensuring the components are folded to specifications, while adhering to safety standards.

Project Consultation: We assess your needs and quote based on the recommend best method.

Machine Setup: We accurately prepare the machine and its tooling to complete the project.

Folding commences: Our skilled operators complete the task as efficiently as possible. Whether it’s 1 piece or 10,000 pieces

Why Trust SmartWeld?

With years of experience in the fabrication industry, SmartWeld is committed to delivering professional workmanship and outstanding customer service. Our highly skilled machine operators will ensure your project is achieved to your expectations, as we work closely with our clients, ensuring every job is completed efficiently, safely, and within budget.

Our promises:

Safety Compliance: Adherence to New Zealand’s safety standards and guidelines.

Skilled machine operators: Qualified and experienced, to provide excellent workmanship.

High-Quality Materials: We only use good quality materials for your project.

Customer-Focused Service: On-time project delivery and clear communication.

What our clients say