Roller Door Spring Replacement

On-Time Project Delivery

We consistently deliver projects on time and within budget, ensuring your deadlines are met without compromising quality.

Customer Satisfaction

With a focus on quality and client relationships, we maintain a high customer satisfaction rate, with a significant percentage of our clients returning for repeat business.

Quality AssurED

Our products undergo rigorous quality assurance, including batch testing and life cycling, ensuring that every item we manufacture meets the highest standards of reliability and performance.

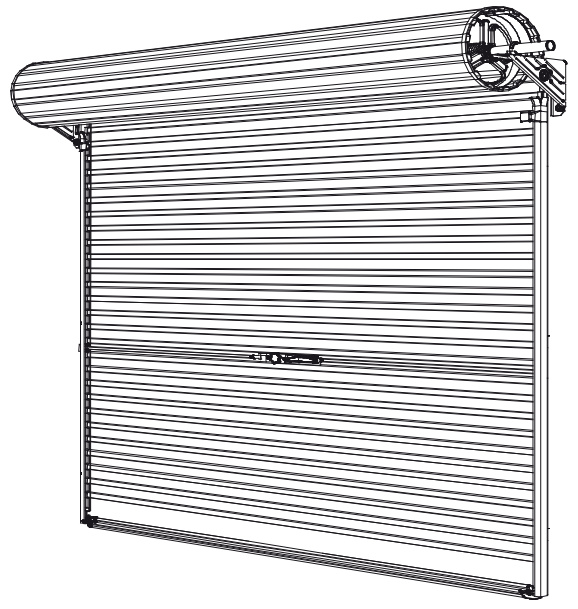

Replacing Roller Door Springs

Like all mechanical systems, roller door springs can experience wear and tear over time. One of the most critical elements of a roller door system is the door spring, which helps lift and lower the door efficiently. Understanding roller door springs, particularly torsion springs, is vital for any homeowner or business owner with a roller door to maintain your entire door system’s durability.

What Are Roller Door Springs?

Understanding Torsion Springs

Torsion springs are the primary type of springs used in roller doors. These springs are mounted inside a barrel above the roller door opening and work by twisting and untwisting to store energy. When the roller door motor or manual operation activates the system, the torsion spring unwinds, allowing the door to open smoothly. Torsion springs are known for their durability and can last for several years if properly maintained. The length of the spring and the wire size can vary, so it’s essential to choose high-quality roller door springs that match your door’s specifications. “Smartspring” premium torsion springs can enhance the overall functionality and longevity of the system.

How to Identify When Roller Door Springs Need Replacement?

Recognising a failing roller door spring is crucial for maintaining the safety and functionality of your door. Some common signs that your roller door spring may need replacement include:

- Difficulty in opening or closing the door

- A loud snapping or popping noise when the door operates

- The door appearing heavier than usual when lifting manually

- The roller door stopping or binding unexpectedly

- Coning during door travel, meaning one side of the door isn’t balanced with the other.

How to Test Roller Door Springs

To test a roller door spring, first, disconnect the motor and attempt to lift the door manually. If the door is difficult to lift or does not stay in place when halfway open, the spring may need tensioning, or it could be faulty. It is advisable to seek professional inspection if you notice any irregularities.

Common Problems with Roller Door Springs

Roller door springs can experience various issues that may hinder their performance. Common problems include:

- Improper tensioning

Can cause the door to operate unevenly or with excessive force - Coning of the curtain or slat

Causing binding in the track guides, because the door is opening faster on one side than the other. - Incorrectly sized springs

Can strain the motor and reduce efficiency - Springs life cycle

The springs selected don’t reach the life cycle expectancy of the door.

Regular maintenance and inspections can help identify these issues early, preventing costly replacements and ensuring smooth operation.

What Is the Process for Replacing a Roller Door Spring?

Unfortunately, there is no easy way to replace a worn out or broken spring in a roller door. Most manufacturers encapsulate the springs in the drum when assembling the door on a production table. Normally a steel tube or metal enclosure of some kind is used to construct the door for rigidity, to attach the door curtain or slats to the drum wheels. This means the door is a sealed unit, so it’s very important to get the springing exactly right on initial manufacturing otherwise it’s a very costly process for the supplier to deconstruct and replace springs.

Due to the high tension stored in roller door springs, it is highly recommended to seek professional assistance unless you have experience handling high-tension springs as an industry trained installer. We wouldn’t recommend anyone trying to the release the spring tension on a roller door and remove the door itself.

Another aspect to consider is the size of a roller door. Industrial doors are very heavy and require specialist equipment to install or remove. Small domestic doors are easily handled, however have the same issue as industrial doors with the springs being concealed within the drum on construction. Domestic doors also have spring tension to consider and may cause serious harm to someone who isn’t an experienced installer, trying to do a DIY repair.

How Much Does It Cost to Replace Roller Door Springs?

It costs time, money and reputation for companies who experience spring issues on their doors.

The last thing a door manufacturer wants is springs to fail on a newly installed door. Customer complaints and warranty claims can damage your company’s reputation, ultimately leading to loss of market share.

You need a quality supplier with good manufacturing processes.

At Smartweld, we have developed our own in-house quality process that we have been using for a number of years. This allows us to control the quality of our product. Our “Smartspring certified” quality regime involves strict processes through manufacturing, starting with material test certs and finishing with documented certs for mechanical testing, before they are delivered to our customers.

Contact Our Engineers

If you need professional assistance when sourcing roller door springs, or if you need advice on sizing, our experienced team is here to help. Contact us today for quality advice and reliable service.

What our clients say