Metal Roll Forming

On-Time Project Delivery

We consistently deliver projects on time and within budget, ensuring your deadlines are met without compromising quality.

Customer Satisfaction

With a focus on quality and client relationships, we maintain a high customer satisfaction rate, with a significant percentage of our clients returning for repeat business.

Quality AssurED

Our products undergo rigorous quality assurance, including batch testing and life cycling, ensuring that every item we manufacture meets the highest standards of reliability and performance.

Precision Craftsmanship for Modern Manufacturing

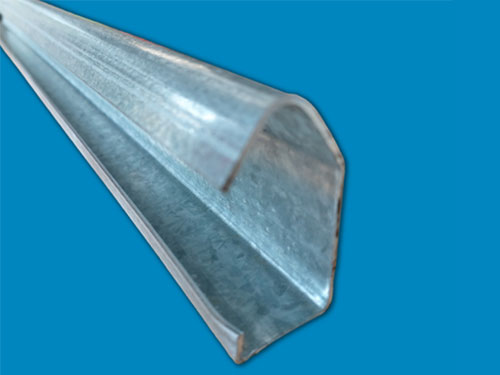

Reinforcing Strut

This anti-sag profile (0.75mm thick, 55mm high, and 65mm wide) is known for its rigidity and strength. It is roll-formed and available in any length, from Zinc coated sheet metal to meet your specific needs. The profile features a unique “vee shape” on each leg, making it easier to secure fastenings into materials like timber, steel, aluminium, and plastic. Perfect for reinforcing a variety of outdoor structures, it’s ideal for strengthening timber fences, steel frameworks, sagging framing, tiny house constructions, trailers, garage doors, and more. This versatile and durable profile offers reliable support across multiple applications, ensuring long-lasting performance.

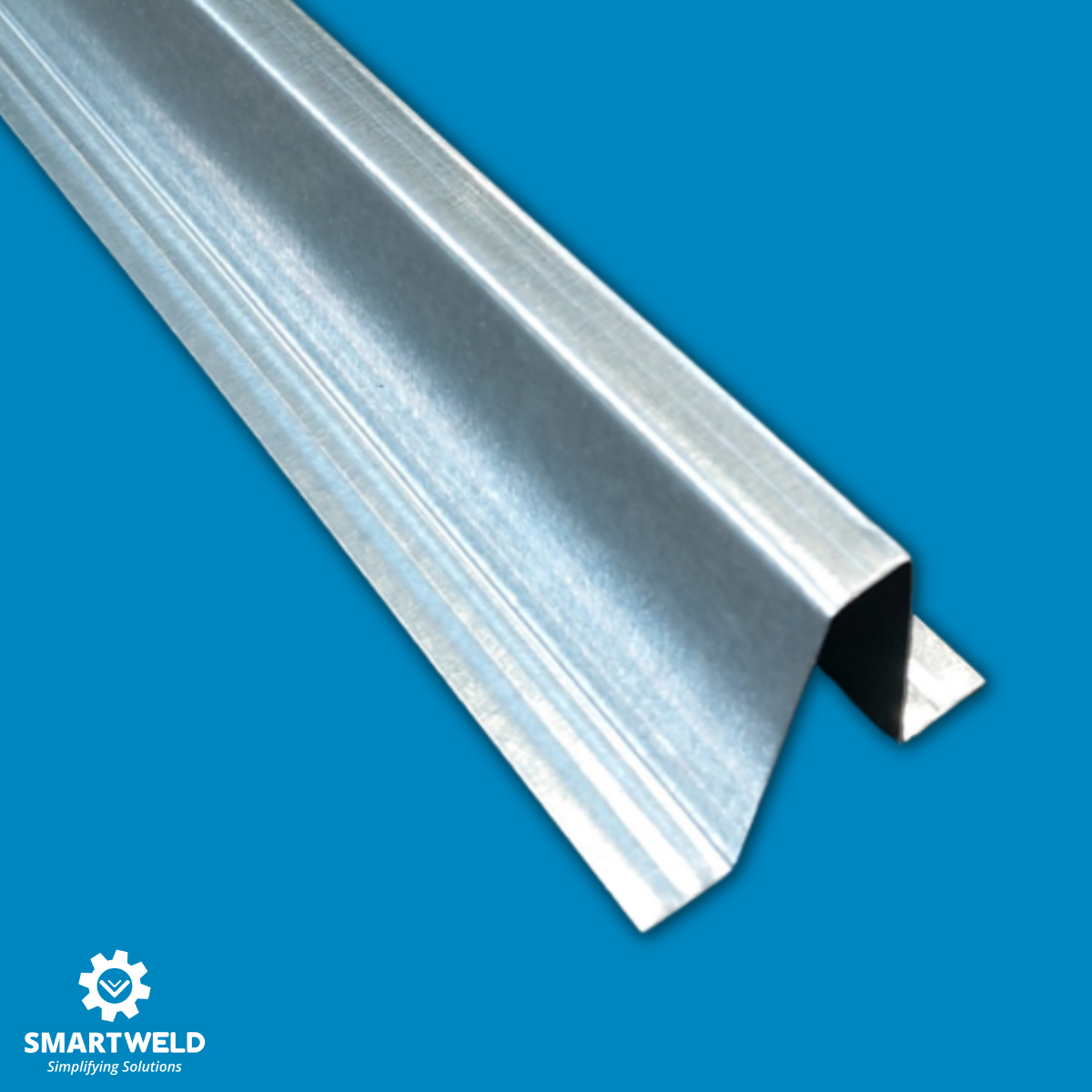

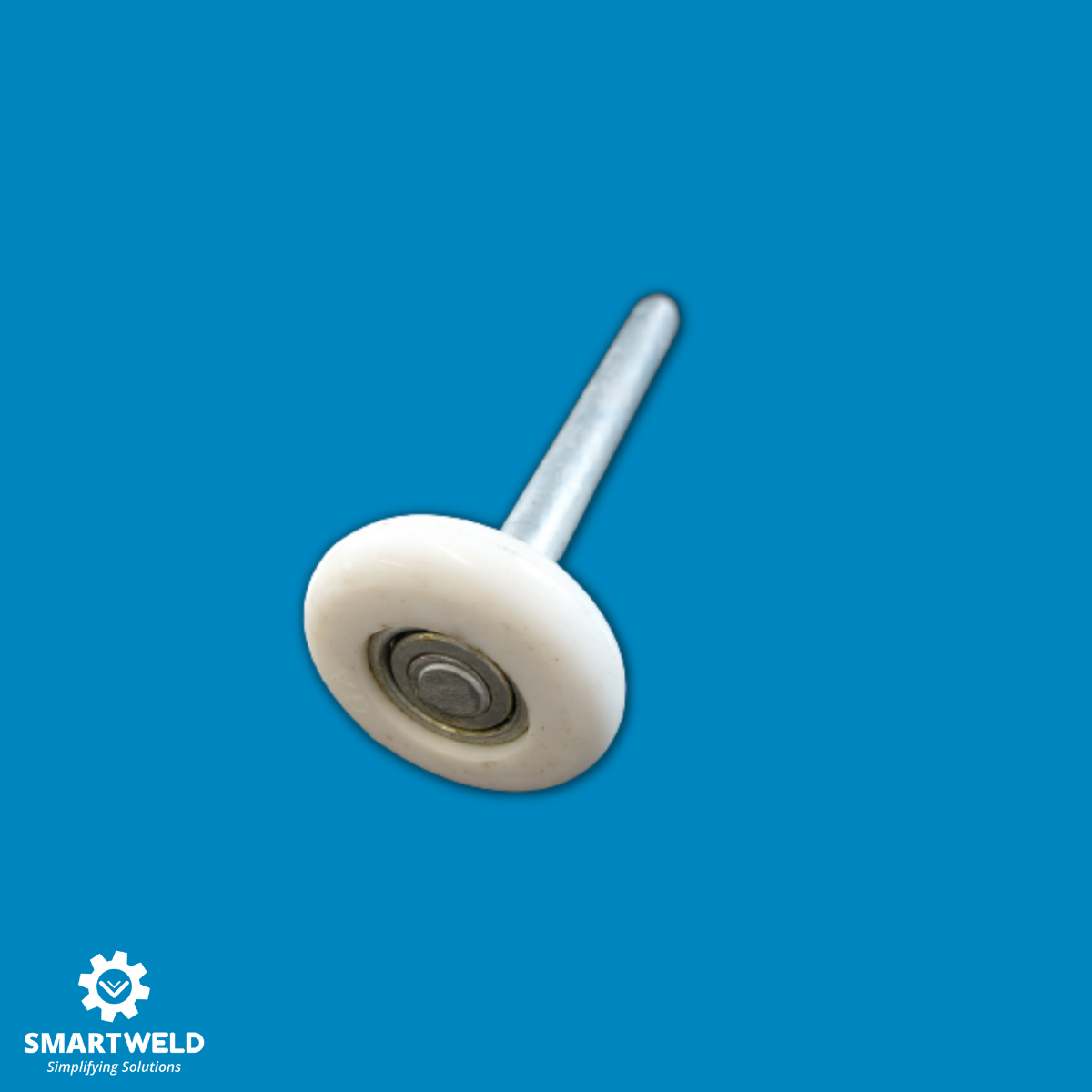

Door Track

Our door track is made from rigid, strong roll-formed 1.6mm galvanized steel, with dimensions of 27mm wide and 55mm high (Zinc coated sheet metal), making it suitable for both indoor and outdoor installations. Unlike other tracks that are limited to short lengths, we can supply custom lengths to meet your needs. Additionally, we offer nylon wheels with roller bearings, capable of supporting up to 35kg per wheel. For heavier loads, simply add more wheels to the track. The wheels can also be supplied with brackets. This combination is perfect for replacing garage door tracks, sliding door tracks, gates, rails, trailers, and more.

What is Metal Roll Forming?

Metal roll forming is a highly efficient and versatile manufacturing process used to create continuous profiles of metal by gradually bending a flat coiled strip of material into the desired shape, using a series of driven profiled hardened rollers. Through the use of a series of precisely calibrated rollers, roll forming ensures dimensional accuracy, superior finish, and exceptional structural integrity in the final product. It is ideal for producing parts in high volumes with minimal waste, while reducing production costs.

Why Choose Roll Forming?

Surface Finish Options

Roll forming supports various coatings, including galvanized, painted, powder coating or other finishes, ensuring parts meet functional and aesthetic requirements.

Cost Efficiency

By reducing waste and enabling high-speed production, roll forming delivers cost-effective solutions for manufacturing large volumes of consistent, high-quality components.

Exceptional Strength

The process enhances the mechanical properties of metal by work-hardening it during the bending, making roll-formed parts more robust and durable. Often extra ribs are rolled into the sheet metal to provide additional structural strength of a product.

Applications of Metal Roll Forming

Metal roll forming is used across numerous industries, including:

Renewable Energy: Frames for solar panels and wind turbine components.

Construction: Roofing, ceiling battens, cladding, and structural framing components.

Roading: Structural supports, trim, and bumpers.

Electrical: Ductwork, channels, and mounting rails.

Roll Forming Services

Why Trust SmartWeld?

With years of experience in the engineering industry, SmartWeld is committed to delivering professional workmanship and outstanding customer service. Our machine operators are trained to handle small and large production runs. We work closely with our clients, ensuring every job is completed efficiently, safely, and within budget.

Our promises

Safety Compliance: Adherence to New Zealand’s welding safety standards and guidelines.

Skilled machine operators: Efficiently processing orders.

High-Quality Materials: We only use good quality materials for roll forming.

Customer-Focused Service: On-time project delivery and clear communication.

What our clients say